Changes that are made to a contract scope of work and modifications of work conditions are among the key causes of conflict in construction projects. When a contractor is faced with changed conditions or needs to work under circumstances that force the contractor to work while its productivity is less than what it expected, the contractor is, in fact, working in the state of inefficiency. The loss of productivity results in monetary damages because working inefficiently forces contractors to incur labor or equipment costs more than what they originally expected. One of the references that claim administration professionals use for quantifying the adverse impact of change on labor productivity is the MCAA labor productivity factors.

The phrases inefficiency and loss of productivity can be used interchangeably. Proving and quantifying the adverse impact of change on the labor productivity of a contractor is, in fact, one of the most challenging topics in construction claims. One of the references that is often used to quantify the adverse impact of change on labor productivity percentages of contractors is a reference published by the Mechanical Contractors Association of America (MCAA) within which labor productivity factors are identified.

MCAA focuses on the special needs of the firms that are involved in heating, air conditioning, refrigeration, plumbing, piping, and mechanical service. In 1971, MCAA published a reference entitled Management Methods Manual, in which it identified factors affecting productivity. The latest MCAA publications, including the 2018 edition of MCAA’s guideline, entitled, Change Orders, Productivity, Overtime—A Primer for the Construction Industry, still contains these labor productivity factors [1]. These productivity factors have also been endorsed by other professional associations including the Sheet Metal & Air Conditioning Contractors’ National Association’s (SMACNA).

The MCAA factors are also known as MCAA labor productivity factors. These factors identify the major causes of labor productivity loss experienced by mechanical contractors. As such, they can be used not only to estimate the adverse effects of particular productivity factors on labor productivity levels but also to measure the extent a contractor has incurred damages as a result of estimated losses of labor productivities encountered over the course of a project.

The MCAA labor productivity factors include factors such as the following:

- Stacking of trades

- Crew size inefficiencies

- Site access issues

- The ripple effect, and

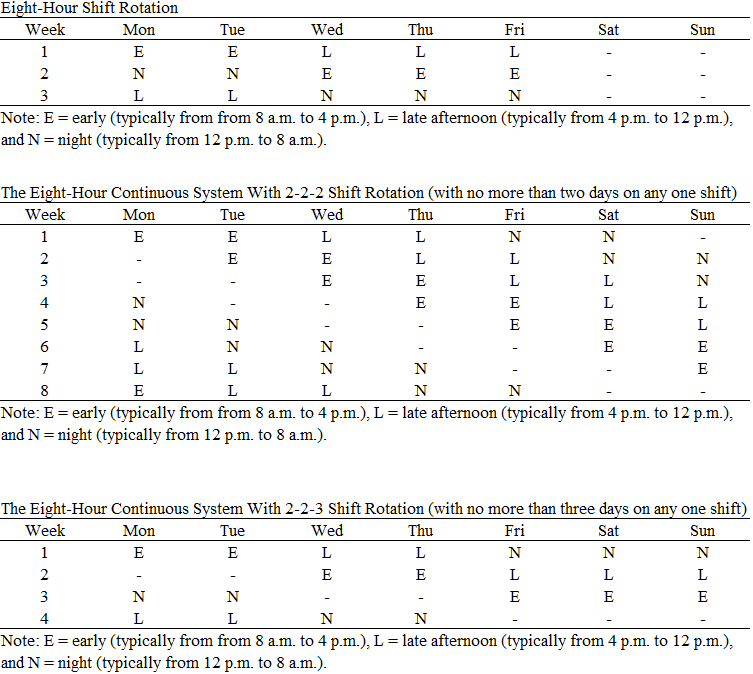

- Overtime and shift work

Some critiques indicate that the MCAA factors are not based on the outcome of empirical studies to determine the percentages of loss of labor productivity arisen from specific productivity factors. However, the MCAA factors have successfully been used in many cases brought to courts or reviewed by boards of contract appeals. An example of these cases is the case of CLARK CONCRETE CONTRACTORS, INC., v. GENERAL SERVICES ADMINISTRATION, in which, the use of the MCAA factors is described as follows:

To assess the impact of unanticipated conditions on productivity …, P&K used a manual published by the Mechanical Contractors Association of America (MCA). This manual was the same one P&K used, with reference to labor rates, in constructing its bid for the project. P&K has used it on other projects to measure similar impacts, and the publication is generally accepted in the mechanical industry for this purpose… We have previously accepted the use of this manual for this purpose as well. Stroh Corp., 96-1 BCA at 141,132; see also Fire Securities Systems, Inc., VABCA 3086, 91-2 BCA 23,743, at 118,902. The manual lists various types of impacts and, for each, a percentage of labor costs which represents loss of labor productivity under each of minor, average, and severe impacts. [2]

It is important to note that MCAA factors can be used both prospectively and retrospectively. In using the MCAA factors prospectively, a contractor may use the MCAA guideline to price a lost productivity element of a change order proposal to quantify the extent that the labor productivity of the contractor may be impacted as a result of a change. In using the MCAA factors retrospectively, a contractor, however, may use the MCAA guideline to retrospectively quantify the impacts of change on the labor productivity as experienced by a contractor. A retrospective quantification of the impacts of change on a contractor’s labor productivity may become necessary because no other method might be available to measure labor productivity of the contractor over the course of the project due to the lack of detailed records of labor hour tracking.

It is important to use the MCAA productivity factors properly. The method is relevant to the work of mechanical contractors but the use of this method for contractors that work in other disciplines may not be appropriate. In addition, if a contractor has maintained proper, detailed records of labor hour tracking over the course of a project, the use of the MCAA labor productivity factors may not be the best choice of the loss of labor productivity assessment method. That is because the presence of detailed records of labor hour tracking over the course of a project may enable a contractor to use a method such as the measured mile method which may be identified to be a more appropriate method depending on the specifics of a case. The measured mile method measures labor productivity levels during a relatively un-impacted reference period with performance on the same or similar work (similar in type, nature, and complexity) during an impacted period. This method then calculates the productivity for both periods of time and identifies the difference between the two as the productivity loss attributed to the impact.

It is important that claims administration professionals assess the circumstances that have given rise to a claim for loss of labor productivity and decide whether the use of the MCAA labor productivity factors is appropriate. Although the MCAA guideline is not based on the outcome of an empirical study to determine the percentages of loss of labor productivity arisen from specific productivity factors, it has successfully been used in many cases brought to courts or reviewed by boards of contract appeals. However, claims administration professionals and experts need to apply the MCAA guideline with careful consideration once the facts surrounding the claim have closely be examined.

References:

[1] Mechanical Contractors Association of America [MCAA] (2018) Change Orders, Productivity, Overtime—A Primer for the Construction Industry, MCAA. Retrieved 24 November 2018, from https://www.mcaa.org/resource/change-orders-productivity-overtime-a-primer-for-the-construction-industry-2/

[2] CLARK CONCRETE CONTRACTORS, INC., v. GENERAL SERVICES ADMINISTRATION. Retrieved from https://www.gsbca.gsa.gov/appeals/w1434015.txt

Author: Dr. Amin Terouhid, P.E., PMP | Principal Consultant

If your project has been affected by change orders and if changes have adversely affected labor or equipment productivity on-site, or if you are interested to find out more about labor productivity factors, please contact us. Adroit’s consultants have demonstrated their expertise in the use of this method and will be able to assist. You may also be interested to read the following articles: