Dr. Amin Terouhid, PE, PMP

This article describes the nature and causes of cumulative impact claims and explores the underlying factors that give rise to cumulative impacts in construction projects.

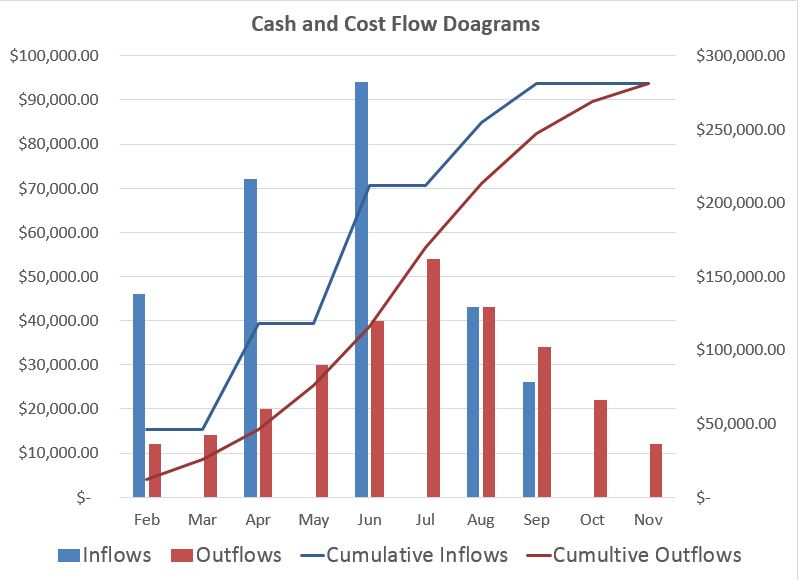

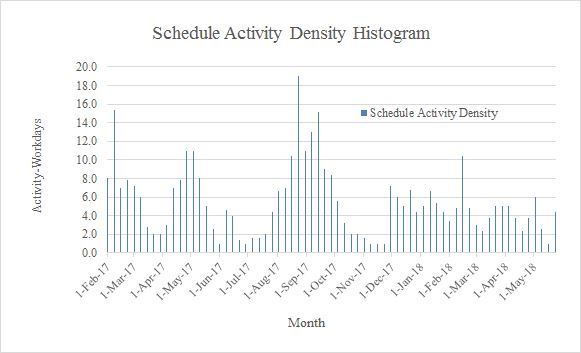

Changes that are made to a contract scope of work and modifications of work conditions are among the key causes of conflict in construction projects. The net cumulative effect of changes is often greater than the sum of the effect of individual changes. This condition may occur when a contractor realizes that the work has been affected by unforeseeable synergistic effects of multiple changes. This condition is typically the case where the collective cost, time, and productivity impacts of the changes have been impossible for the contractor to foresee while considering each of the effects individually. The collective impacts of these types of changes are typically identified as the cumulative impact. The Construction Industry Institute (CII) describes cumulative impact as follows:

When there are multiple changes on a project and they act in sequence or concurrently, there is a compounding effect – this is the most damaging consequence for a project and the most difficult to understand and manage. The net effect of the individual changes is much greater than a sum of the individual parts. [1]

A cumulative impact claim typically arises when the changes to a contractor’s scope of work are so numerous and overlapping that the contractor had no reason to know that it was not fully pricing each of the change orders at the time it negotiated the changes one at the time.

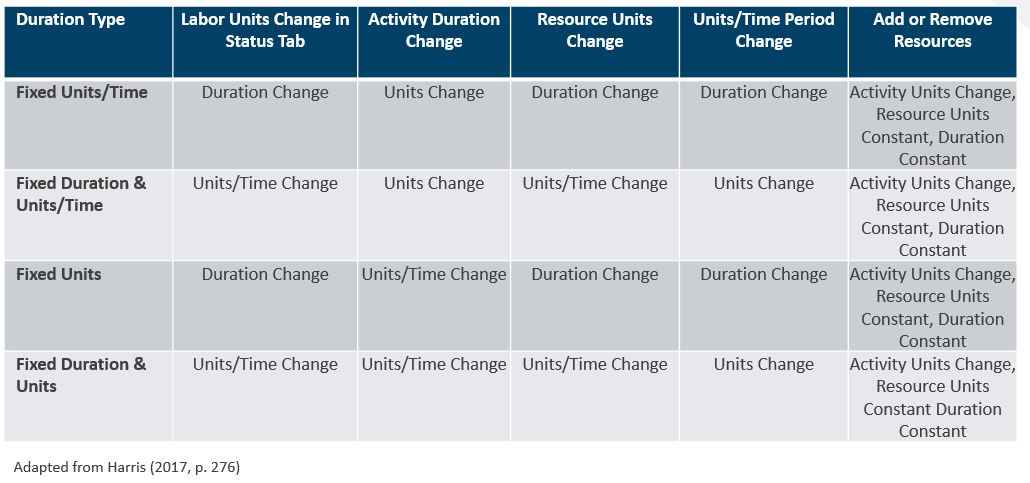

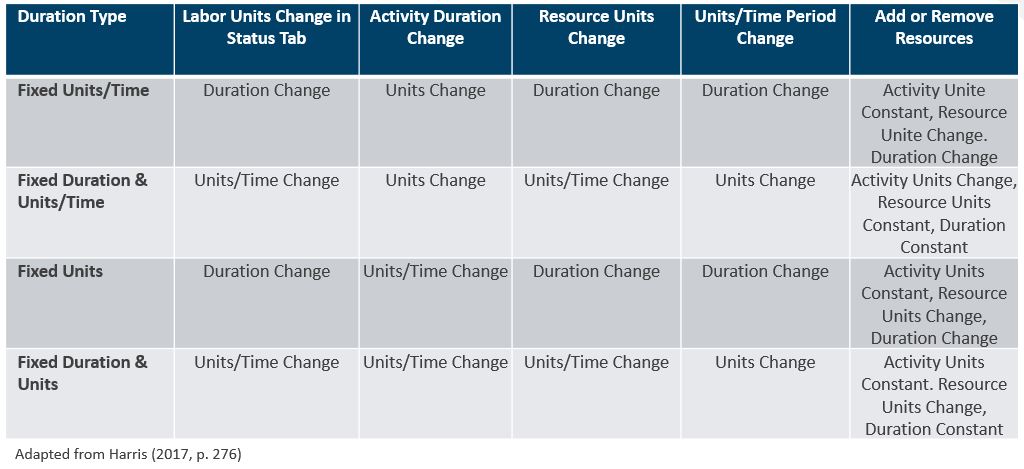

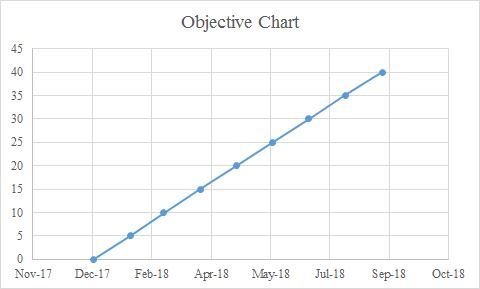

Cumulative impacts have unique characteristics that differentiate them from other types of impacts. In the case of cumulative impacts, multiple changes occur whose cumulative effect is greater than the sum of the effect of individual changes. It is important to note, however, that the multiple changes that have a cumulative impact on a scope of work should typically be labor-related changes. Therefore, in assessing cumulative impacts, the dollar value of the changes that have occurred is not as important as their intensity in terms of the number of labor hours required to execute the changed work. The number of labor hours needed to perform the change is critical in evaluating cumulative impacts because the ultimate objective of a cumulative impact claim is to demonstrate the extent of loss of labor productivity arisen from the synergistic effects of multiple changes. It is typically expected that the more labor-intensive the changes are, the greater their individual and cumulative impacts will turn out to be.

To quantify the damages resulted from the cumulative impact of multiple changes, a variety of methods can be used some of which include actual cost method, estimated cost method, total cost method, modified total cost method, should have spent method, measured mile, and jury verdict [2]. What is important, however, is to be able to demonstrate that the damages have resulted from the causes in reference. The success of a cumulative impact claim depends primarily on the ability to establish the cause and effect relationships between the causes in dispute and the resultant cumulative impact. No definitive standard has been established or accepted by courts or dispute boards to quantify the loss of productivity claims that contain a cumulative impact component; therefore, it is typically challenging to prove that damage calculations accurately represent the damages incurred as the sole result of cumulative impacts.

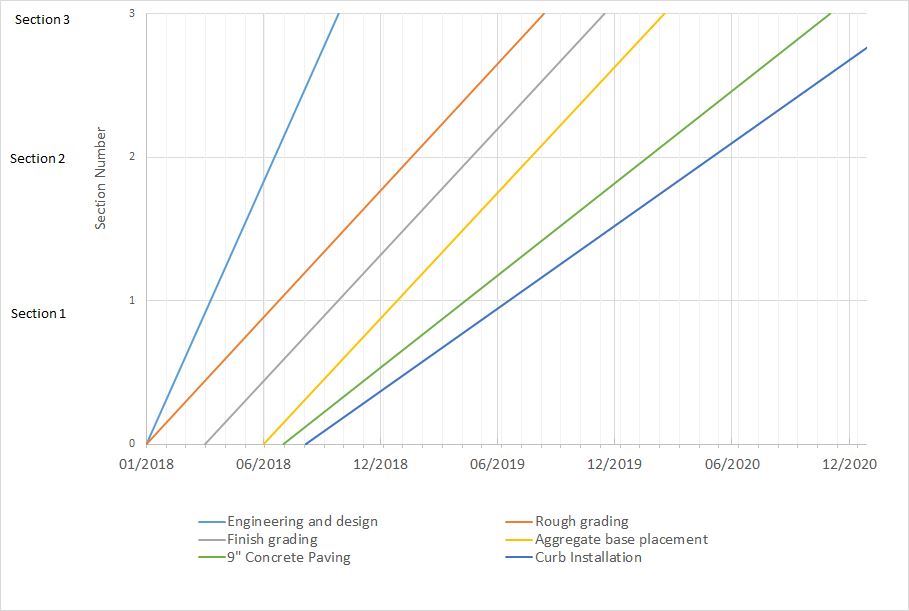

As part of a cause and effect analysis, a written narrative that describes the chain of events is essential. The narrative should properly establish the relationship between causes and resultant impacts. Preparing such a written description of the events, causes, and their effects is a minimum requirement for parties involved in a claim to demonstrate the cause-and-effect relationships between various events and resultant damages. Adequate supporting documents such as excerpts from the contract, change directives, meeting minutes, relevant correspondence, and filed reports can play an important role in substantiating the arguments and supporting the statements contained in the claim.

One of the methods that are often used to assess causal relationships between causes and effects in complex construction claims is the system dynamics method. Complex cases of claim involve multiple claim components that are typically intertwined and interrelated; and as such, assessing these cases may require advanced methods such as system dynamics. This method is an approach within the system thinking domain which considers complex systems as a holistic set of interrelated components to provide a better understanding of the system. Four important questions that are asked in the process of developing a system dynamics model include what is the issue at hand, what is flowing into and gets accumulated in the system representing the problem, where and how does it accumulate, and what factors cause it to flow.

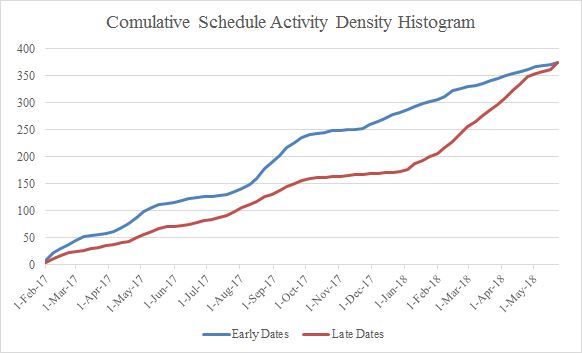

Cumulative impacts should not typically be measured right after a change or during the course of the project while the impact of changes has not fully been materialized. Instead, cumulative impacts are typically measured towards the end of the project to ensure the full adverse, synergistic effect of multiple changes can properly be identified and qualified. Untimely evaluations may partly represent the adverse cumulative impacts that take shape over time.

References:

[1]. T. Hester, John A. Kuprenas. & T. C. Chang (1991). Construction Changes and Change Orders: Their Magnitude and Impact. CII Source Document 66.

[2]. Jones, R. M. (2001). Lost productivity: Claims for the cumulative impact of multiple change orders. Pub. Cont. LJ, 31, 1.

If your project has been affected by multiple change orders and they have adversely affected labor or equipment productivity on-site, or if you are interested to investigate the adverse effects of cumulative impacts on your project, Adroit will be able to assist in assessing these impacts. For more information, please contact us.