The critical path represents a project’s longest continuous sequence of activities in the project schedule. This path determines the earliest time that the project can be completed. To complete a project earlier than its originally-planned completion date, the project longest path is typically shortened. Shortening a project schedule may be costly and result in unintended consequences. For example, schedule compression may cause stacking of trades and ultimately result in loss of labor and equipment productivity. Nevertheless, project teams may choose to shorten a project schedule due to a variety of reasons such as catching up to achieve the planned dates that are affected by delays or due to a need to achieve some milestone dates earlier than expected.

Due to the potential impacts of schedule compression on the project, the project teams should use proper strategies to shorten the project longest path. In accelerating project activities, priority needs to be given to the critical activities because these activities drive the expected project completion date in the schedule. If a number of options exist, priority is typically given to those critical activities whose crashing is less costly. Improper implementation of acceleration plans may result in less than expected time savings, unexpectedly high costs of crashing, quality or safety issues, and loss of labor or equipment productivity. It is important to note, however, that acceleration is not the only option for shortening the longest path.

Depending on the type of the project and its scope of work, project teams may have a number of options to compress project schedules. The following table outlines some of the example methods in each of the main phases of engineering, contracting and procurement, and implementation:

Phase Method Method Description

Engineering Constructability review and analysis The review of designs to ensure designs can practically be implemented with cost-effective means and methods.

Incorporate modular components in design The incorporation of modular components in design to ensure less time is needed to be spent on the jobsite to implement these components.

Reuse designs and plans The reuse of previously-used design elements may result in saving design time and efforts.

Incorporate standard or typical components in the design The use of standard or typical designs may help the design team save time and efforts in implementing designs.

Incorporate pre-engineered or on-the-shelf components in the design The incorporation of pre-engineered or on-the-shelf components may reduce the need for designing new elements.

Contracting and procurement Fast-tracking The creation of an overlap between design and procurement or an overlap between procurement and implementation activities may result in time savings.

Outsourcing The assignment of work to outside entities instead of implementing all activities in-house may help to use in-house resources in more effective ways.

Find alternative or equivalent modular products or systems The use of alternative or equivalent products or systems may help to save time that would have otherwise been used to fabricate or supply items.

Implementation Improve work sequence The improvements to the work sequence or betterment of the work schedule may help project teams identify time saving opportunities.

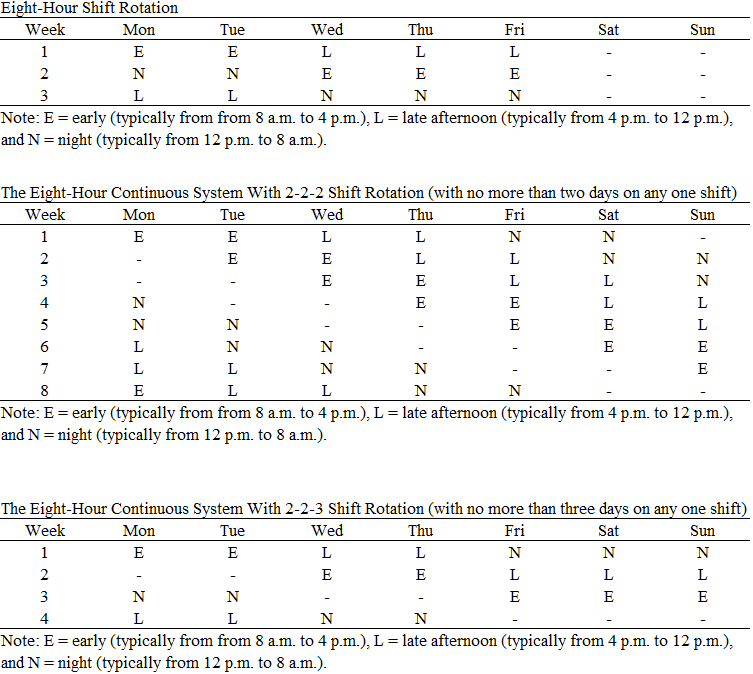

Shiftwork and overtime Working overtime or working in periods other than daytime hours may help project teams make more progress in the same or shorter amounts of time.

Expend more resources in the same or shorter time periods The use of higher resource usage rates and spending more resources in the same or shorter time periods may help project teams increase progress achievements.

Incentivized working schemes The use of incentivized schemes may encourage project teams to complete activities in a shorter amount of time or work in a more effective manner.

Because of the potential impacts of schedule compression techniques on the project, the project teams should use proper strategies to shorten the project longest path. Acceleration is not the only option to shorten the longest path. If a project team is intended to shorten the project longest path, it is recommended that the team chooses the most appropriate strategies in each of the main phases of engineering, contracting and procurement, and implementation to ensure the schedule can properly be compressed using a cost-effective manner that fits the project needs.

—

Our posts to the Insights page share fresh insights and seasoned advice about many project and construction management topics. To have the Insights monthly newsletter delivered automatically to your email inbox, please subscribe here.