In preparing project time schedules in Oracle’s Primavera P6, project planning and scheduling professionals need to properly select duration types. Primavera P6 uses the following two formulae to determine units of work:

Resource Units = Resource Units per Time Unit * Duration

Remaining Resource Units = Resource Units per Time Unit * Remaining Duration

Based on these two formulae, the user is able to make one or two element(s) of the equation fixed, and input or change the other element(s). That way, Primavera P6 will calculate the remaining elements of the equation. To determine which element(s) of the formula to solidify, the users need to take the nature of the work or information at-hand into account and make an informed decision concerning the elements that need to be solidified. This decision then helps the user to choose among the four main types of activity duration types.

Four types of activity duration types can be defined in Primavera P6. They include 1) Fixed Duration & Units, 2) Fixed Duration & Units/Time, 3) Fixed Units, and 4) Fixed Units/Time. The following discusses each of these activity duration types in more depth:

1- Fixed Duration & Units: This types of activity duration is used in Primavera P6 when the duration and the amount of the resources are known and supposed to remain fixed in the schedule. It is recommended that project planning and scheduling professionals use this duration type for time- and budget- constrained projects prior to making schedule updates. The two possibilities include the following:

- Option 1: Duration does not change when resources are added or removed, or if the user changes Units/Time.

- Option 2: A change to the Duration will change the Units/Time; however, Units remains unchanged.

2- Fixed Duration & Units/Time: This type of activity duration is used in Primavera P6 when the duration and resource performance are known and are supposed to remain fixed (i.e., unchanged) in the schedule. In other words, activity durations remains unchanged in the schedule; however, the remaining units change. If an activity is supposed to be completed within a certain, fixed time frame irrespective of the number or amount of resources being assigned to the activity, this activity duration type is the right choice that needs to be used for that activity. This activity duration type is most often used if the user uses task dependent activities (not resource dependent activities). The two possibilities include the following:

- Option 1: Duration does not change when resources are added or removed, or when Units/Time changes.

- Option 2: A change to the Duration will change the Units; however, Units/Time remains unchanged.

The use of this activity duration type locks the duration, and the default Units/Time (productivity) values for each resource added. Nevertheless, this activity duration types allows the overall Unit cost to increase when resources are assigned to the activity. It is recommended that project planning and scheduling professionals use this duration type during the planning phase because doing so will force Primavera P6 to honor activity duration estimates and increase the work (Units) and, therefore, the budget, based on additional quantities of work performed (Units/Time).

It is important to note that this duration type disables the User Preferences, Calculations tab option Recalculate the Units, Duration, and Units/Time for existing assignments based on the activity types.

3- Fixed Units: Primavera P6 users need to use this type of activity duration if the amount of work needed to complete an activity (e.g., 8,000 bricks to be laid) is fixed. If this type of activity duration is used, decreasing units per time causes the activity duration to increase; however, if the user updates the duration or units per time, the Units remain unchanged. Increasing the resources allocated to an activity whose duration types is Fixed Unit, decreases the activity duration. It is best to use this activity duration type where the duration is “resource dependent” (and not “task dependent”). If in a project, the budget is set and it is difficult to get additional cost increases approved, the Fixed Units activity duration type is the right choice assuming the other above-mentioned requirements are also satisfied.

4- Fixed Units/Time: Primavera P6 users need to use this type of activity duration if the activity has fixed productivity output per time period (regardless of activity duration). In other words, this duration type is supposed to be used when the user would like the resource units per time to remain unchanged while the activity duration or units change. For example, if a piece of equipment requires two workers to operate, the Fixed Units/Time duration type might be the right choice. When the duration of an activity whose duration type is Fixed Units/Time increases, the amount of budgeted labor units also increases while resource Units/Time remains unchanged. This activity duration type is most often used if the user uses resource-dependent activities.

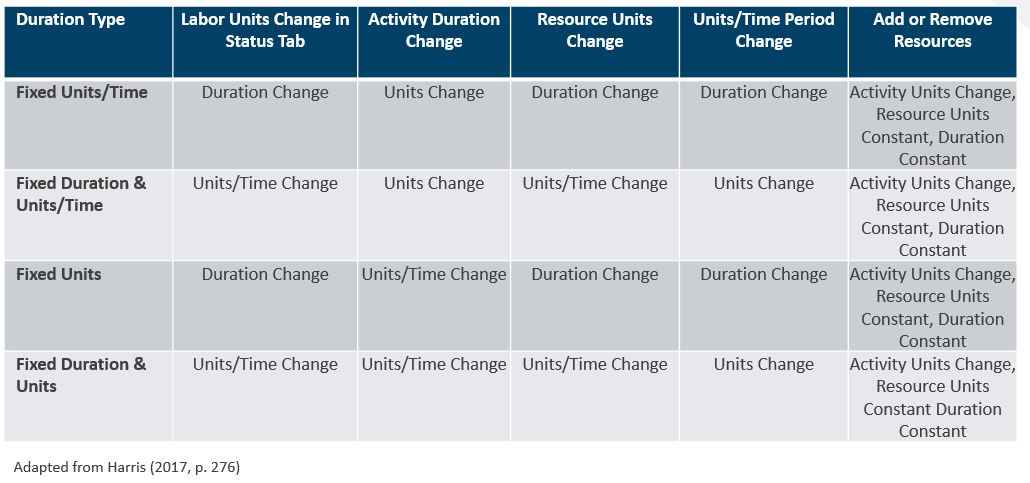

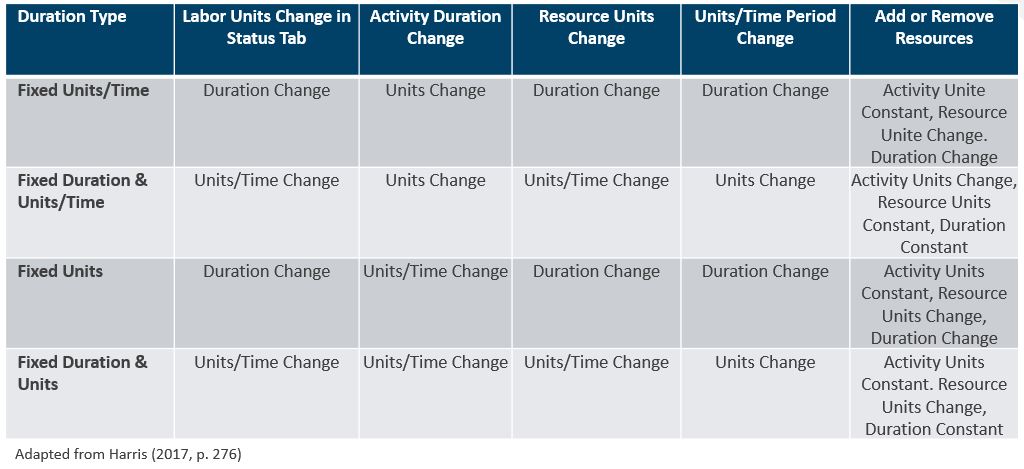

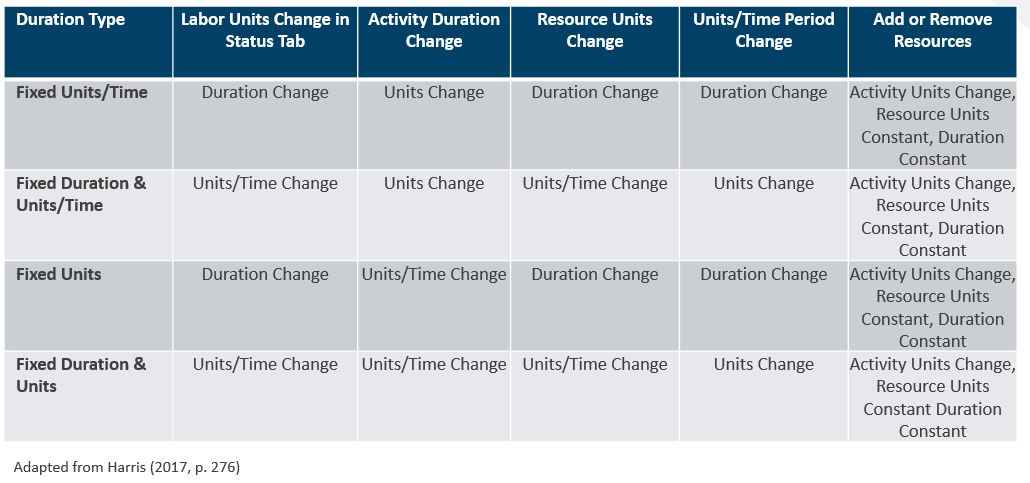

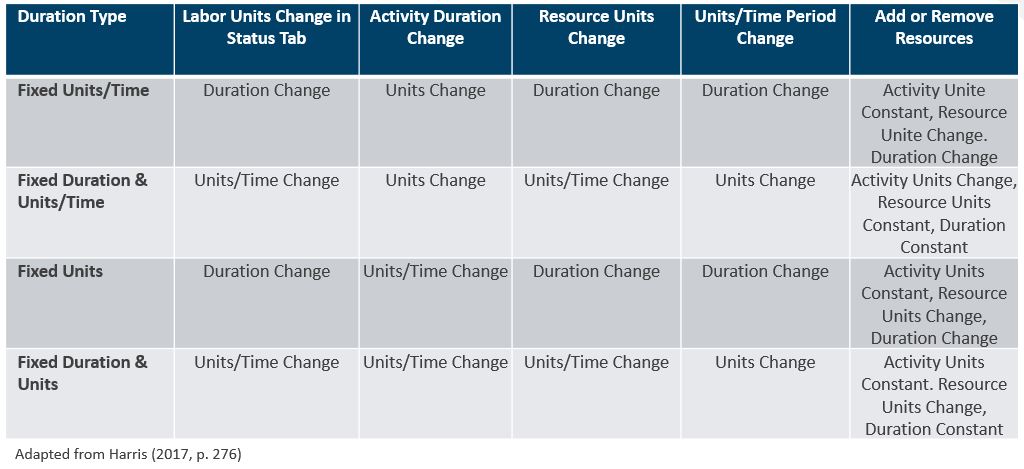

In addition, users have the choice to choose to preserve “the Units, Duration, and Units/Time for existing assignments” or recalculate “the Units, Duration, and Units/Time for existing assignments” in the User Preferences, Calculations tab of Primavera P6. This choice, as well as the choice of activity duration types, determines what element(s) remain(s) unchanged and what element(s) change(s). These scenarios are outlined in the following two tables:

The User Preferences, Calculations tab option “Preserve the Units, Duration, and Units/Time for existing assignments” is chosen when the user adds or removes multiple resource assignments on activities but would like Units, Units/Time, and Durations to remain unchanged when additional resources are assigned to an activity. When the User Preferences, Calculations tab option “Preserve the Units, Duration, and Units/Time for existing assignments” is selected, here are the various scenarios that are encountered:

The User Preferences, Calculations tab option “Recalculate the Units, Duration, and Units/Time for existing assignments” is chosen when the user adds or removes multiple resource assignments on activities and would like to determine a resource assignment’s remaining values based on the activity’s duration type. When the User Preferences, Calculations tab option “Recalculate the Units, Duration, and Units/Time for existing assignments” is selected, here are the various scenarios that are encountered:

As discussed, four types of activity duration types can be defined in Primavera P6. They include 1) Fixed Duration & Units, 2) Fixed Duration & Units/Time, 3) Fixed Units, and 4) Fixed Units/Time. It is important to pay attention to the nature of work that is being performed to select the right type of activity duration types. This article defined each of this activity duration types and explained where each option needs to be used and what the implications of using these duration types are from the scheduling perspective.

References:

Harris, Paul E (2017). Planning and Control Using Oracle Primavera P6 Versions 8 to 17 PPM Professional. Eastwood Harris Pty Ltd.

Oracle (2018). Primavera P6 Professional User Guide Version 17. Available online at: https://docs.oracle.com/cd/E80668_01/English/User_Guides/p6_pro_user/helpmain.htm?toc.htm?62789.htm